Actually Let Me Attempt To Move The 'Meat' of the thread over,,,I won't bore anyone with un-interesting pictures of the gun in stock form.

Finish of the gun is like an AEG, doesn't really have the gritty, rugged aesthetic of the MILSPEC M4A1. The Feel of the gun is fantastic, very solid, good weight, fire controls are sturdy, selector is hard to move Which Is How It Should Be - Once In Position It Doesn't Move A Bit!

Take Down Pin is not of the MILSPEC design the same for the front pivot pin. However both pins fit very tight and are very solid with both pins protruding out of the reaction side of the lower receiver mimicking the look and function of MILSPEC receiver pins.

The bolt stop is pinned to the reaction side of the lower receiver just like MILSPEC.

It moves freely and is actuated by the magazine easily. With the receivers separated, insert the empty magazine and the bolt catch moves up crisply and solidly. The bolt catch design is so more surface area is contacting on the carrier, the carrier is also cut to accommodate the bolt catch or carrier catch as it were for better positive engagement - VERY NICE!!!

Still Feeling the sting of the Craptastic AGM Whore That Took ALL My Money And Refused To Put Out!! I Nervously Loaded up the magazines and shot the gun - the recoil Is Surprisingly Solid. But Not A Kick In The Nuts Like The WA - AGM - There Is Less Felt Recoil - However the bolt carrier group cycles quickly and crisply. Felt more refined than rudimentary almost like a snap. In this session with 2 KJW Mag - Ghey - zines (Not A Fan Of The Ghey Ass Look Of These Mags!) I nervously shot through the first mag until the bolt locked back. Quickly Loaded the fresh mag and shot again until empty, topped off both mags again with BBs and repeated - 7 Times! As soon as the gun surpassed 3 mags it had ALREADY Out Paced Anything The AGM Did - EVAR - With Zero Failures or Incidents! By the 7th magazine I was in full tactical forward lean while shooting - WHY - Because the front of my shorts was hurting my boner and I Had to lean forward to alleviate the pressure! It chrono'd at 420fps with .25 g BBs using propane gas, mmm the smell of it!

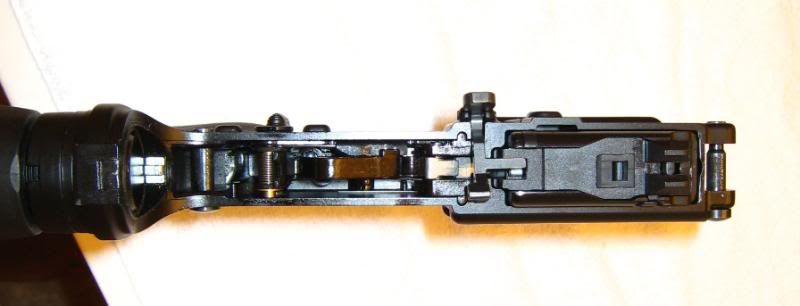

Ok then, for the moment I was confident enough the gun wasn't going to go all Lindsay Lohan on me. I decided to look under her skirt and see if I could get a good view like Anakchan when he looks up while walking up the stairs at Shinjuku station! The guns smooth cycling is due mainly by the bolt / carrier group. The front half of the bolt is the polycarbonate cup that houses the nozzle to propel the BB. Very light, well designed with a pronounced BB extractor the gas expands in the cup propelling the BB forward and once the BB is gone the gas pushes the remainder of the bolt carrier back into the buffer tube and back again completing the cycle. The bolt carrier is much lighter, thinner than her WA / WE sisters.

It is a sturdy, formed steel carrier with a metal weight welded into the back of the carrier right where the carrier mates with the buffer. Which explains why the gun shoots so smooth, all the weight is to the back, all the business is up front creating a quick snappy action with half the weight and the violence of action of the WA design.

Another major design difference is the buffer being smaller in diameter and made of Delrin, smaller buffer spring with the buffer sliding inside a polished brass tube. Very clean and silky smooth just like the Zohan likes it! I am sad to be unable to put my Magpul A.S.A.P. Plate on the gun as the buffer tube is actually a brass tube with very fine threads. The buffer tube visible to the operator is merely a skin that is fastened down over the inner brass tube with one fitting over the other like how and inner barrels resides inside the outer barrel.

Yet another major design change is the hop up bucking is located on the inner barrel. Not surprised you say, well some of you have seen it before as it is the VSR-10 hop up bucking. The adjustment is located in the upper receiver placed right in the forward most position ejection port. Turn dial in design is difficult to turn as it adjusts the hop up bucking. Which is fine by me as I don't want it rattling loose messing with my adjustment mid skirmish. I adjusted the hop up and shot at a door handle at 50 yards with shot after repeatable shot! In Short People The Hop Up Works Like Fucking Magic! Better than anything I had on my AGM - By Far!

Well, engineer by nature I could not, would not let her sit there with her school clothes on. Oh No, if she's going to be on my arm, She Has To Be The Hottest Bitch In The Room - it was time to make her look like the saucy minx she is!

I had to make her at ease and go slow, so the plain stock had to go and on went the MILSPEC Magpul CTR. Fits slightly loose but securely pins into every detent adjustment all the way down.

Next was the Magpul trigger guard, stock one has the spring pin in the front at the magazine well - roll pin at the pistol grip. Magpul is long set screw at the magazine well - roll pin at the pistol grip.

Magpul MOE Grip was like hey buddy who wants to party? Well the stock pistol grip was suddenly the fat ugly chick in the crowd and she just fell off the gun in pure shame! One thing to note - the stock KJW pistol grip cap screw is much larger than the cap screw used on the WA / AGM so be sure to save the stock one and use it. Another thing to note is to be careful not to lose the tension spring for the selector switch. With the pistol grip removed it is exposed just like the MILSPEC or WE.

The front set came off real easy, especially with the supplied tools to do the job. The outer barrel is all metal; the front section of the barrel where it connects to the metal body is a different make than the metal of the front barrel that is visible from the front sight post forward. The A2 flash hider is press fit onto the end of the barrel and is held on by set screw for good measure. The front sight post is pinned and will only remove one way in one direction as one side of the pins are shouldered. So pay attention as to which side is bigger before attempting remove.

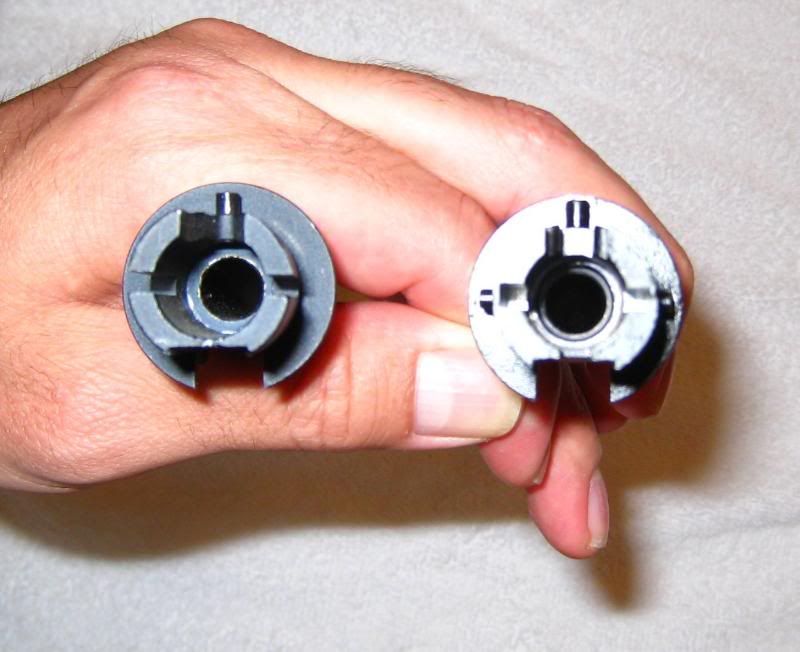

The attachment point into the metal body is nearly exactly as an AEG. They look identical until compared side by side and you'll note there is an extra notch cut into the bottom side of the barrel.

That notch is to allow the BB extractor on the underneath of the bolt nozzle to move freely under the hop up assembly but safely into the barrel extension with out destroying the extractor. Also in the inner bore of the outer barrel needs to have a step drilled into to properly seat the hop up bucking / inner barrel assembly securely into the barrel extension.

Otherwise the hop up adjustment will not work, the bolt will slam into the improperly cut barrel destroying itself, you'll tear up the hop up bucking or All three if you're an unlucky bastard!

I test fit my G&P Defender front set for the WA, the barrel nut fits fine, the hand rails fit fine, the gas tube & gas block fit fine, The WA Barrel = No Go! I was expecting that like Oprah expects cake which is why I had my Classic Army AEG CQB outer barrel at the ready. Good friend of mine with a machine shop and more importantly CNC Milling Machinery was there to save this little lady like Bill Clinton on a trip to Korea. FIRST Took All The Measurements From How the Inner Barrel W/Hop Up Assembly fits into the Stock Outer Barrel assembly. This Is The Important Part - Wrote Those Down - Checked Them Again - Holy Shit They Were the Same?? Essentially on the outer barrel we had to cut a notch to accommodate for the BB extractor travel into the barrel extension. It needed to be .300" deep and .156" wide allowing for .010" clearance on either side of the BB extractor. The amount of material that needs to be removed from the inside diameter of the outer barrel where the hop up bucking / inner barrel assembly firmly seats In Bore Depth is .079" The milling bore bit diameter size is .420" and Blam - You Successfully Converted An AEG Barrel For Use On The New KJW Hotness!

Assembled the front set - Test fired - Verified the Hop Up Adjustment - Verified Good - Shot 5 More Magazine Through - BCG Worked Fine - Finished Assembling The Gun -

- Shot 2 More Mags Through Making a Total of 14 Mags Today Alone So I Would Call It A Successful Day - Lets See About Tomorrow Huh?

Hard Part Is Over Fellas - Now The Fun Part Begins - I Will Shoot The Hell Out Of this Gun And Report Back